Centerliner

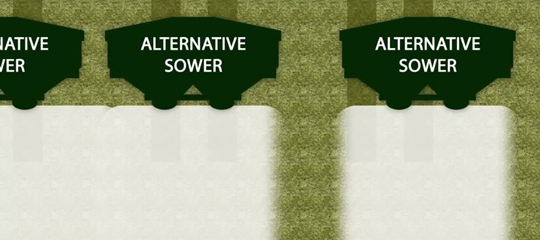

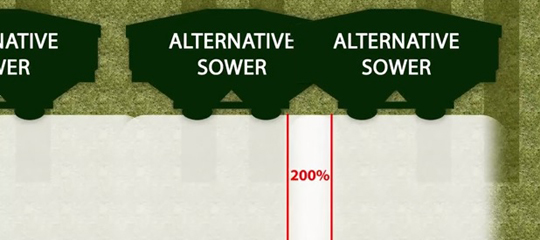

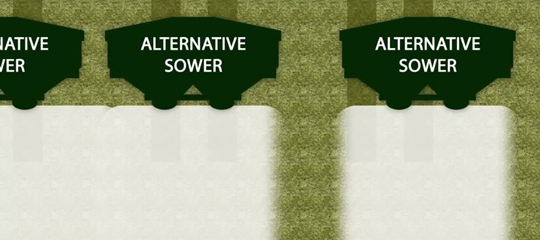

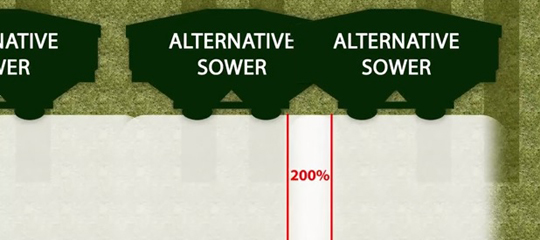

On most fertilizer spreaders, the spinner discs rotate from centre to outside (seen from the rear). Each d ing pattern. These two patterns are then laid against each other in the middle behind the tractor. Only a very accurate dose rate setting, that has to be repeated when switching to another type of fertiliser, can prevent stripes behind the middle of the tractor due to a wrong overlap.

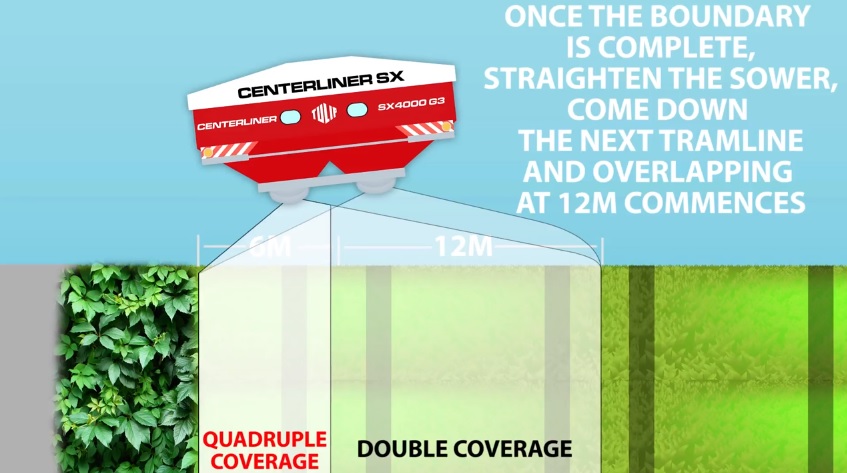

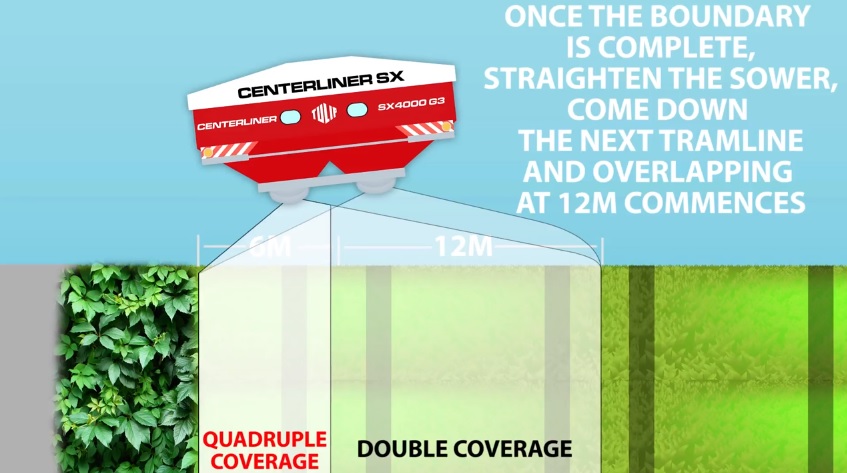

The Centerliner does not have this problem because the spinner discs rotate in the opposite direction; therefore, the two spreading patterns overlap each other completely along the entire spreading width.

This is in fact a full, double overlap.

With most twin-disc spreaders, the spreading pattern slopes steeply towards the sides. The adjoining working bout has to link up with previous bout, which means that even minor driving faults will easily lead to stripes in the crops.

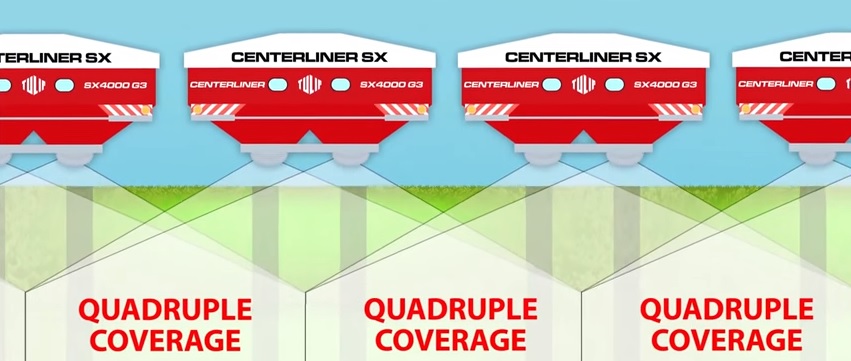

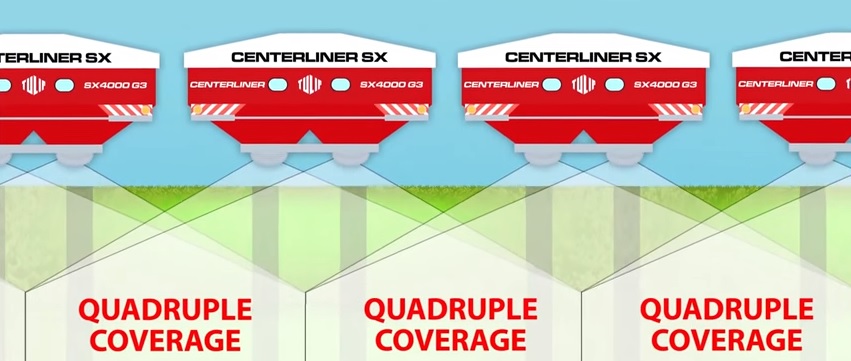

The Centerliner spreads up to the previous tramline, which means this problem doesn’t apply. Hence a driving error of 1 meter or more is a lot less critical and doesn’t disturb the combined spreading pattern. So not only does the Centerliner provide a double overlap per working pass, but it does the same with each consecutive bout. Therefore we can state that the TULIP Centerliner provides 2x a double overlap. Every square meter in the field receives 16 small doses of fertiliser. As a result the machine is very forgiving for user errors, which makes setting up and using the machine easier for you.

The special shape of the spoons is the result of many tests. The suction power of the spoons together with the forced dose result in a constant and even supply of fertilizer. The spoons of the left spinner disc are positioned at a 45° angle compared to the spoons of the right disc. This results in no collisions between fertilizer coming from different discs. The result is an even and synchronised dose. The bowls are very close to the spinner discs for an accurate spreading pattern even on inclines. The drop point is in the centre so the fertilizer gently accelerates along the vanes instead of getting smashed by it.

The Centerliner does not have this problem because the spinner discs rotate in the opposite direction; therefore, the two spreading patterns overlap each other completely along the entire spreading width.

This is in fact a full, double overlap.

With most twin-disc spreaders, the spreading pattern slopes steeply towards the sides. The adjoining working bout has to link up with previous bout, which means that even minor driving faults will easily lead to stripes in the crops.

The Centerliner spreads up to the previous tramline, which means this problem doesn’t apply. Hence a driving error of 1 meter or more is a lot less critical and doesn’t disturb the combined spreading pattern. So not only does the Centerliner provide a double overlap per working pass, but it does the same with each consecutive bout. Therefore we can state that the TULIP Centerliner provides 2x a double overlap. Every square meter in the field receives 16 small doses of fertiliser. As a result the machine is very forgiving for user errors, which makes setting up and using the machine easier for you.

The special shape of the spoons is the result of many tests. The suction power of the spoons together with the forced dose result in a constant and even supply of fertilizer. The spoons of the left spinner disc are positioned at a 45° angle compared to the spoons of the right disc. This results in no collisions between fertilizer coming from different discs. The result is an even and synchronised dose. The bowls are very close to the spinner discs for an accurate spreading pattern even on inclines. The drop point is in the centre so the fertilizer gently accelerates along the vanes instead of getting smashed by it.

Unique features of the Centerliner:

- 2 x 4 spoons rotating from outside to centre, resulting in a quadruple overlapped spreading pattern

- Hydraulic shutter control

- Ease of use, rate setting is very simple

- Guards for a clean tractor

- Walterscheid PTO shaft

- SX: Two threaded hopper sieves (SE: Two punch hole sieves)

- SX: Different gear sets possible

- SX: Standard towing eye

- SX: Heavy duty one-piece hopper extension

- Standard: Side spreading by hydraulically tilting the machine

- Optional: Border spreading with Centraside